Automated Dial Indicator

Testing Machine

Description Functions Specifications Accessories Video

Description

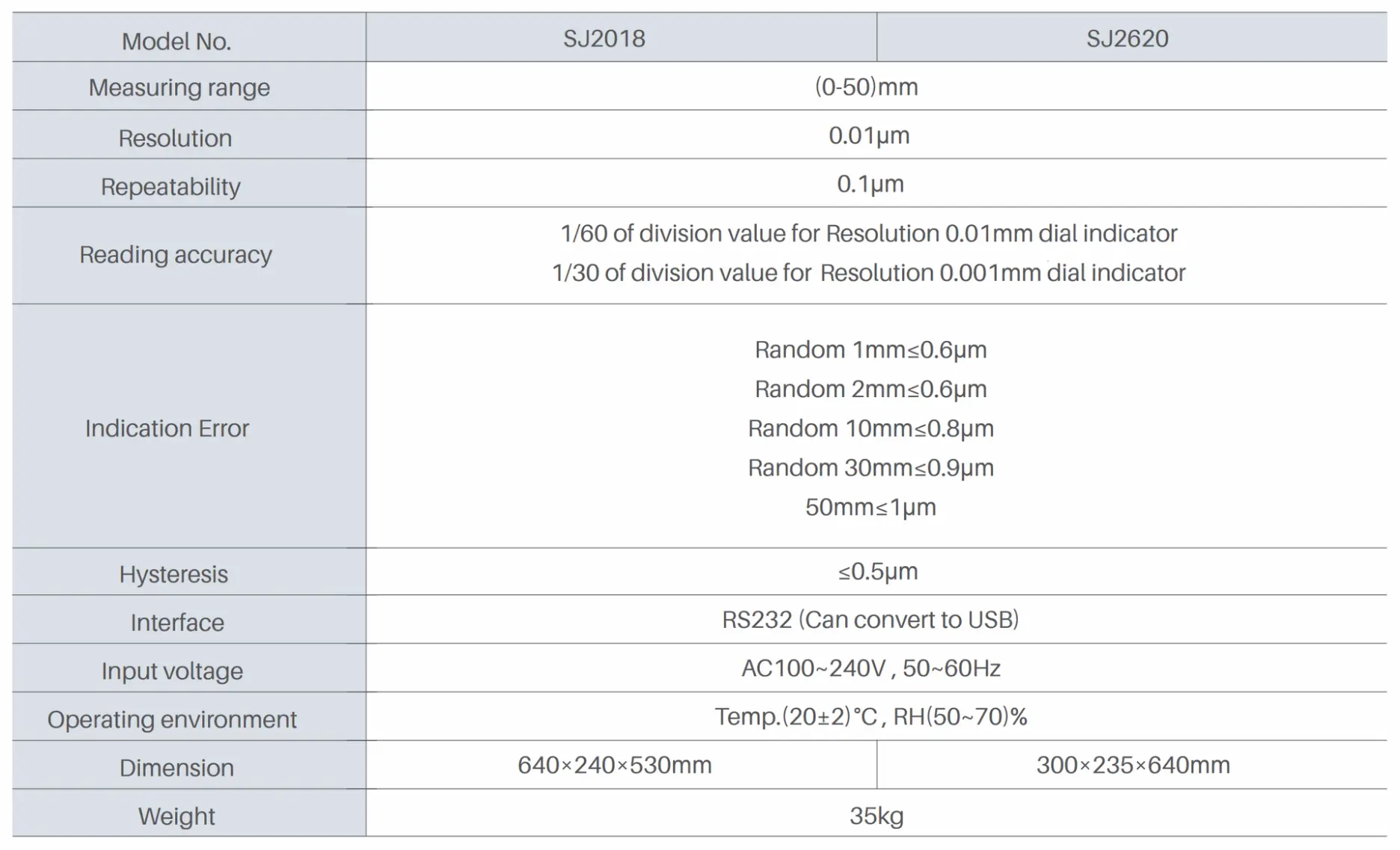

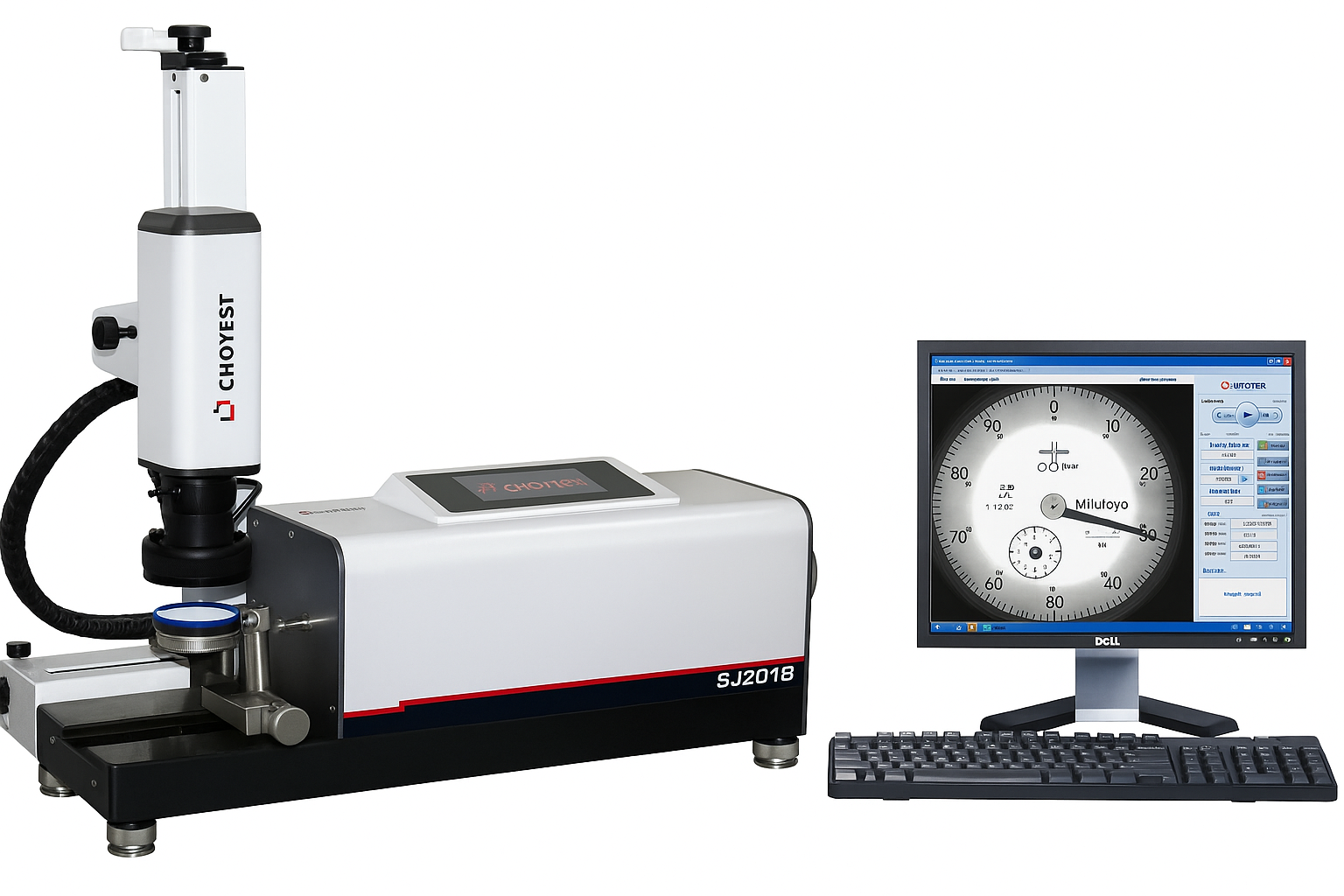

Welcome to a new standard in efficiency and accuracy for gauge calibration. The CHOTEST SJ2018 and SJ2620 are fully Automated Dial Indicator Testing Machines, engineered to replace time-consuming and operator-dependent manual calibration processes.

These systems automate the entire calibration cycle for a wide range of dial indicators, dial test indicators, and lever-style dial gauges. Simply mount the gauge, and the machine performs precise measurements, records data, and generates compliant calibration certificates—all with minimal operator intervention.

The SJ2018 is a high-precision solution designed for the rigorous demands of calibration laboratories and quality departments that require top-tier accuracy.

The SJ2620 offers robust performance and full automation for high-through put environments, making it ideal for manufacturing cells and frequent, repetitive calibration tasks.

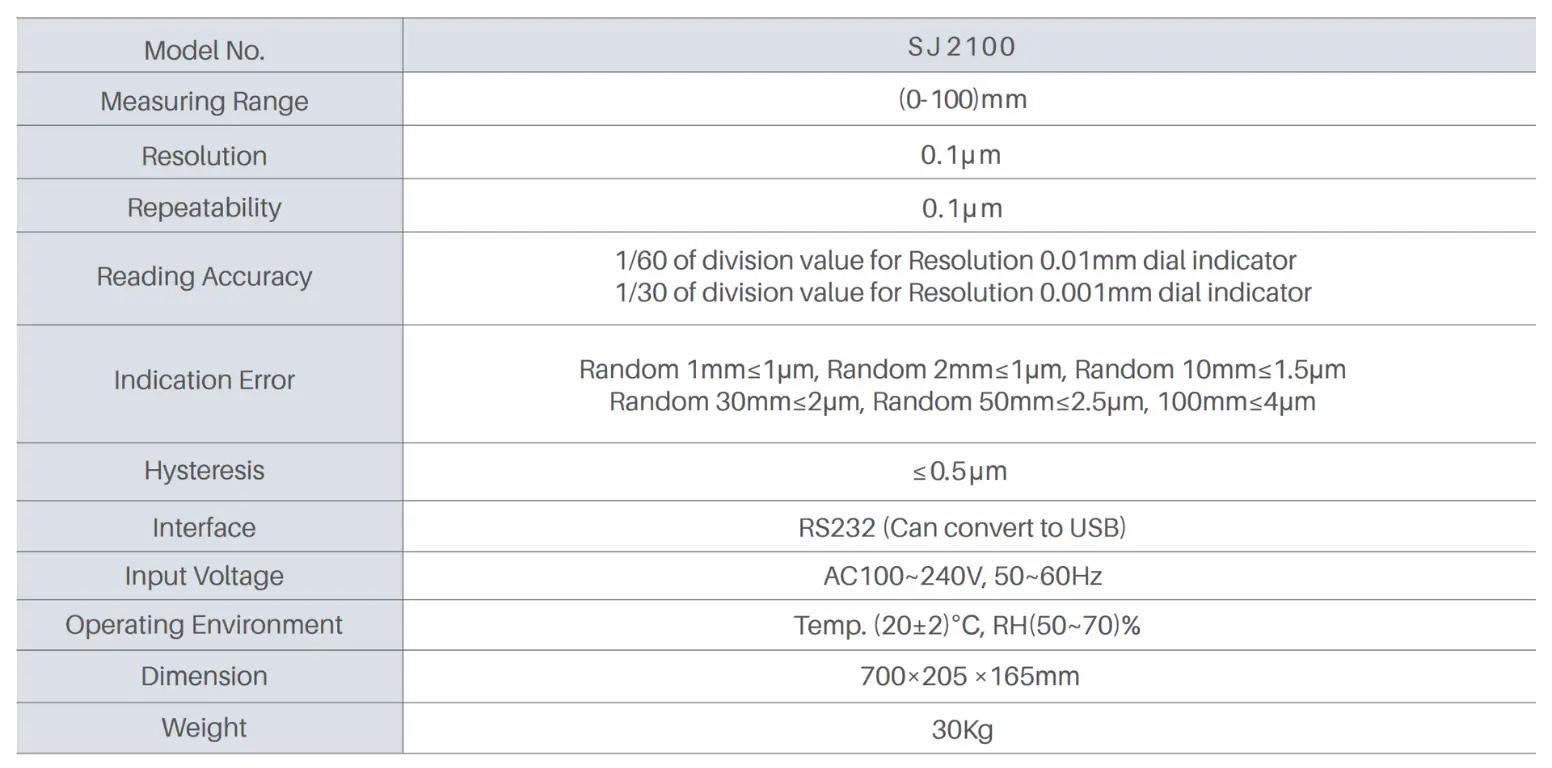

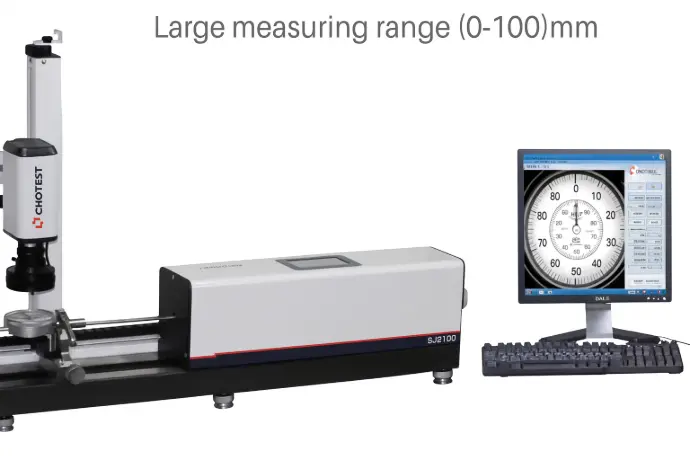

The CHOTEST SJ2100 Dial Gauge Tester is a manual calibration solution engineered specifically for long-travel dial gauges, with an impressive measuring range of up to 100 mm. Designed for workshops and laboratories, this tester combines robust mechanical construction with high-precision electronic measurement systems to ensure your dial gauges and lever-type indicators meet stringent international standards.

Key Benefits:

Full Automation: Eliminate human error and subjectivity. The system auto-aligns, measures, and calculates results based on international standards like ISO, JIS, and DIN.

Unmatched Efficiency: Drastically reduce calibration time from hours to minutes, increasing your lab's capacity and throughput.

Traceable Accuracy: Ensure your measurements are traceable to national standards with our high-precision laser interferometer system.

Compliant Reporting: Automatically generate detailed calibration reports and certificates, ensuring full audit readiness.

Streamline your metrology workflow, ensure consistent results, and free up your skilled technicians for more complex tasks with the CHOTEST Automated Dial Indicator Testing Machines.

Functions

1. Artificial intelligence:

Do not need manual reading & recording & calculating and manual adjustment with hand wheel or microdrum.

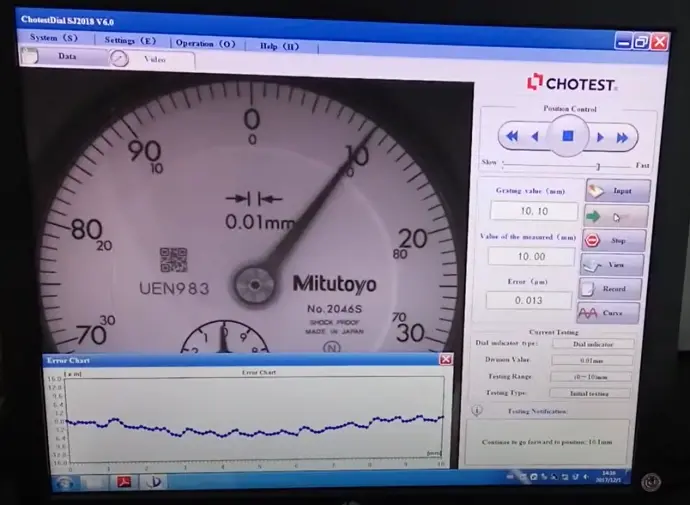

(1) Scale and indication value are identified automatically by the CCD camera which completely simulates manual reading, without observed, read and recorded by operator

(2) Function of automatic zeroing without manual zeroing before testing;

(3) A motor controlled by computer drives measuring spindle to arrive measuring point accurately, without manual adjustment by hand wheel or microdrum

(4) Powerful software automatically processes and qualifies the measured data, finally generates test result, additionally all test records can be queried, displayed, saved, printed.

2. Special light source:

(1) Patented no-reflective light source(Patent No.: ZL200620056214.1)

(2) If the surface of dial indicator is convex, the no-reflective light source is necessary to assure reliability of test data.

3. New patented slider:

National utility model patent(Patent No.: ZL201220239454.0) Eliminate gap in forward – reverse measuring by reducing the wear between the slider and the guide rail; High repeatability: significantly improve lifespan of the slider and guide rail.

4. Humanized design:

Thanks to user-friendly interface, operation of software is extremely simple. With Humanized design for both machine and software, the operator can be trained to use it in a short time. Particularly the system can identify pointer of dial indicator and acquire the indication value of object accurately even if the dial indicator is not in the right center of camera, so the dial indicator can be installed fast, and that simplifies the operating procedure and save operating time.

5. Large-capacity database

With built-in large-capacity storage space for database, the system can record and save all test records automatically.

6. Powerful print Support user-defined template of report(curve, sheet or error value). Test data can be saved automatically, particularly a number of test reports can be printed at once.

Accessories

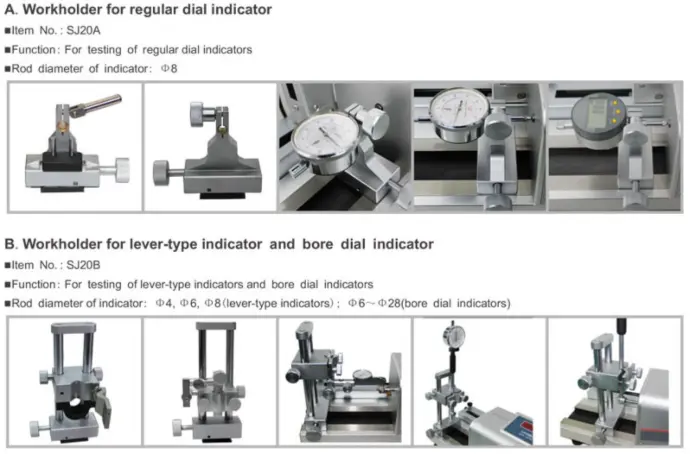

1. Gauges & Holders

Dial Indicator Holder (for securing the gauge under test)

Fixture for Dial Test Indicator (lever-style gauge)

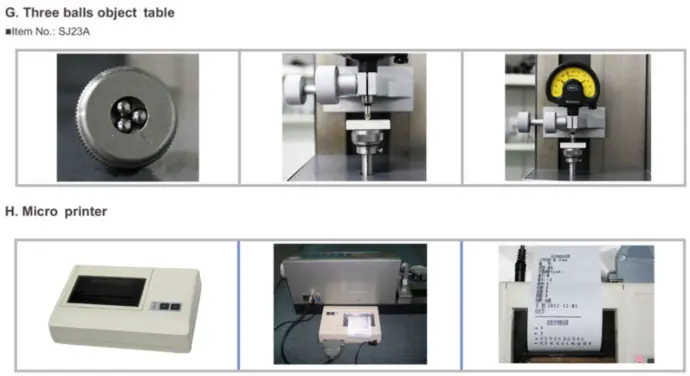

2. Calibration Standards

Standard Ring Gauge (for error verification of the testing machine itself)

3. Control & Interface

Precision Joystick (for manual control of machine movements)

Industrial Control Computer (integrated into the system)

4. Software & Data Management

Specialized Calibration Software

Capability to print calibration reports and certificates

5. Critical Internal Components (Core Measuring System)

High-Precision Glass Scale (for displacement measurement)

High-Precision Laser Interferometer (as the primary reference standard)

Summary:

The SJ2018 is supplied as a complete, ready-to-use system. The key accessories focus on holding different types of dial indicators, the internal precision measuring systems (laser interferometer/glass scale), and the integrated computer with specialized software for automated operation and reporting.

Dial gauge measurement by SJ2018 Fully automated dial gauge tester

Dial gauge measurement by SJ2018 Fully automated dial gauge tester

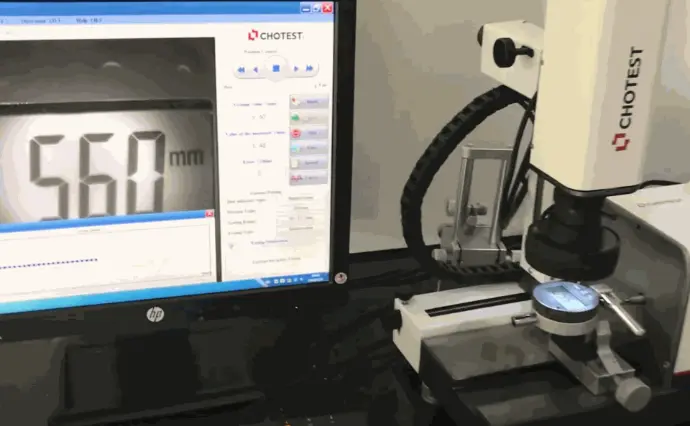

SJ2620 Automated dial indicator testing machine measures dial gauge.

SJ2620 Automated dial indicator testing machine measures dial gauge.

How to measure digital dial indicator by SJ2018

Measurement procedure of digital dial indicator by SJ2018