CHT series

Description Data Export Shooting & Calculation Auto Batch Meas. AI Edge Finding Profile Tol. Accessories Applications Specifications Video

Description

Auto data export

- Can output Excel, Word, PDF, TXT reports and AutoCAD files.

- Support Q-DAS transmission according to designated format.

- Support data exchanging via HTTP or socket protocol.

- Support exporting data to designated excel f ile according to designated template in real time.

- Output SPC analysis report, which includes statistical values (such as CA, PPK, CPK, PP, etc.) and control charts (such as mean and range charts, mean and standard deviation charts, median and range charts, single value and moving range chart).

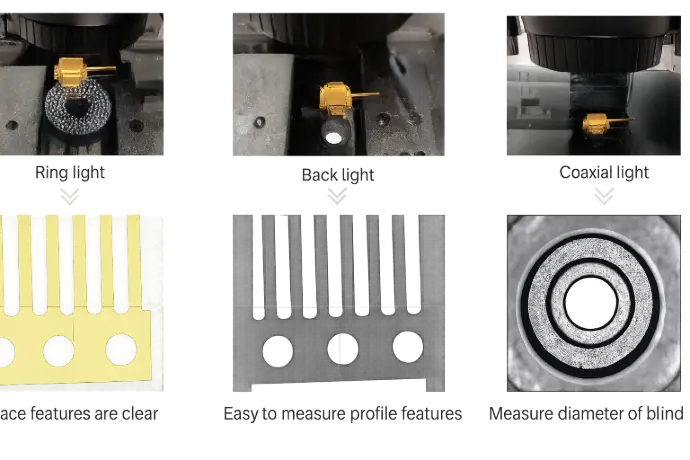

Flexible shooting and precise calculation

Support segmental programming control of surface light, transmitted light and coaxial light, automatically identify the measurement position, and obtain uniform and stable measurement results every time.

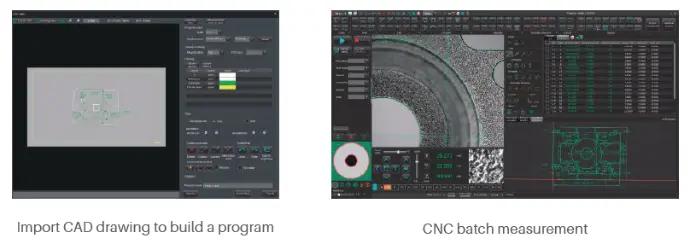

Auto batch measurement

- The program matches the coordinate system of the workpiece, automatically executes the measurement process,supports the import of CAD drawings and Gerber drawings, and coordinates system matching measurement.

- In the CNC fixed coordinate system mode, batch measurement can be performed quickly and accurately.

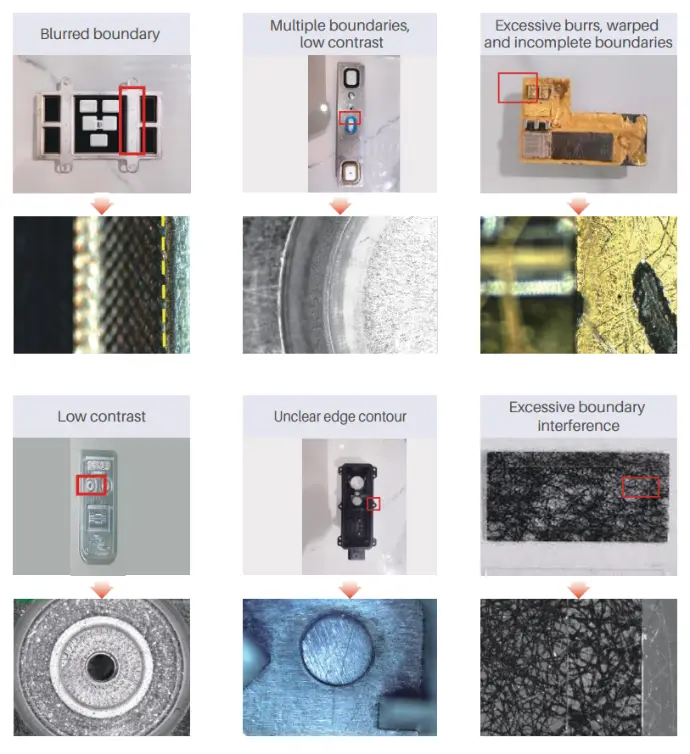

AI edge-finding technology

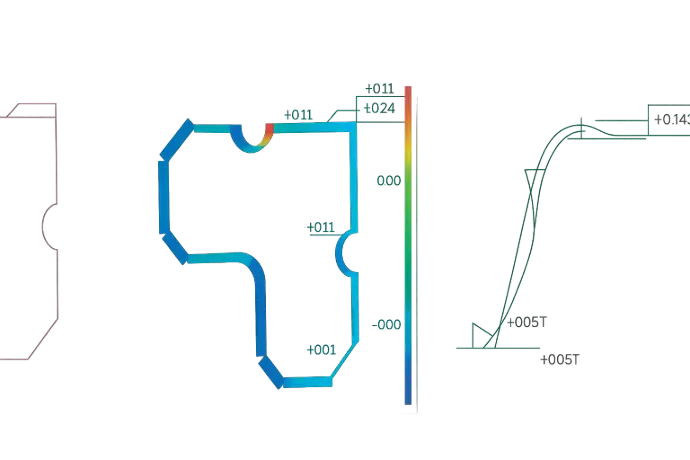

Profile tolerance

Multiple prof le-extracting tools can be used to extract profile with complex edges, as well as import a set of prof le points at specif ed locations for extraction. Can evaluate profile by non reference, single reference, and double references. Errors are displayed with color bands, which are intuitive and clear.

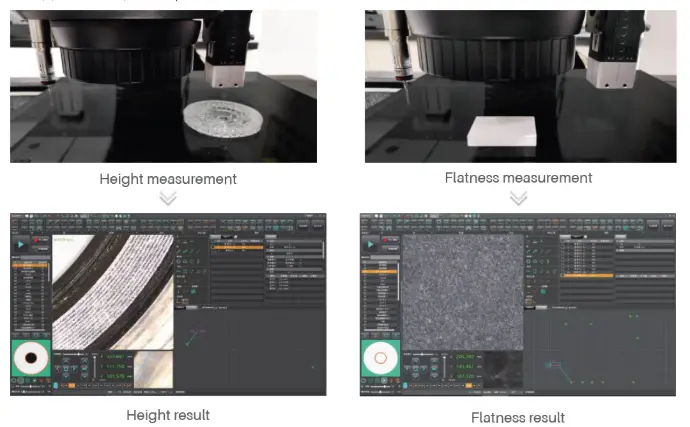

Various accessories

- Equips a touch probe or optical probe to measure height and flatness and realize 2.5D space measurement.

- Supports external input from digital calipers and height gauges.

- Supports label printers.

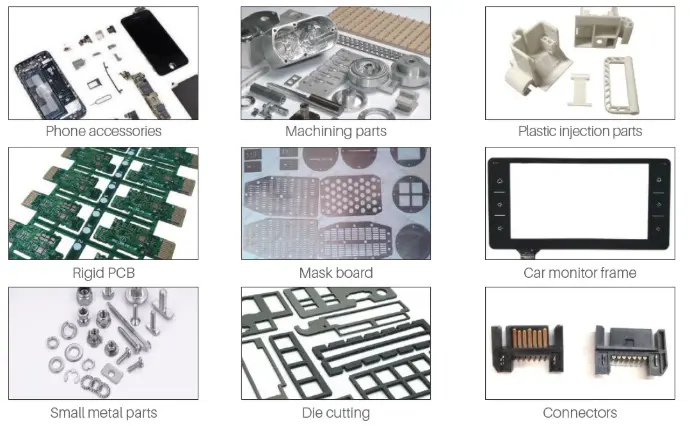

Application

- Phone accessories

- Machining parts

- Plastic injection parts

- Rigid PCB

- Mask board

- Car monitor frame

- Small metal parts

- Cutting parts

- Connectors

Chotest - Flash Measuring Machine - Smart Image Dimensional Measuring System -

The CHOTEST Flash Measuring Machine eliminates traditional errors by allowing free sample placement, automated focusing, and operator-independent consistency. It can measure up to 100 dimensions in seconds with automated reporting for maximum manufacturing efficiency. This system delivers a fast, easy, and consistently accurate measurement experience.

Measurement of Keyboard Frame using Flash Measuring Machine Series VX3500

To add a fourth column, reduce the size of these three columns using the right icon of each block. Then, duplicate one of the columns to create a new one as a copy.

Sieve measurement with CHOTEST CHT Vision Measuring Machine - Fast and easy