Novator Series

Automatic Video Measuring Machines - Flying mode

Description

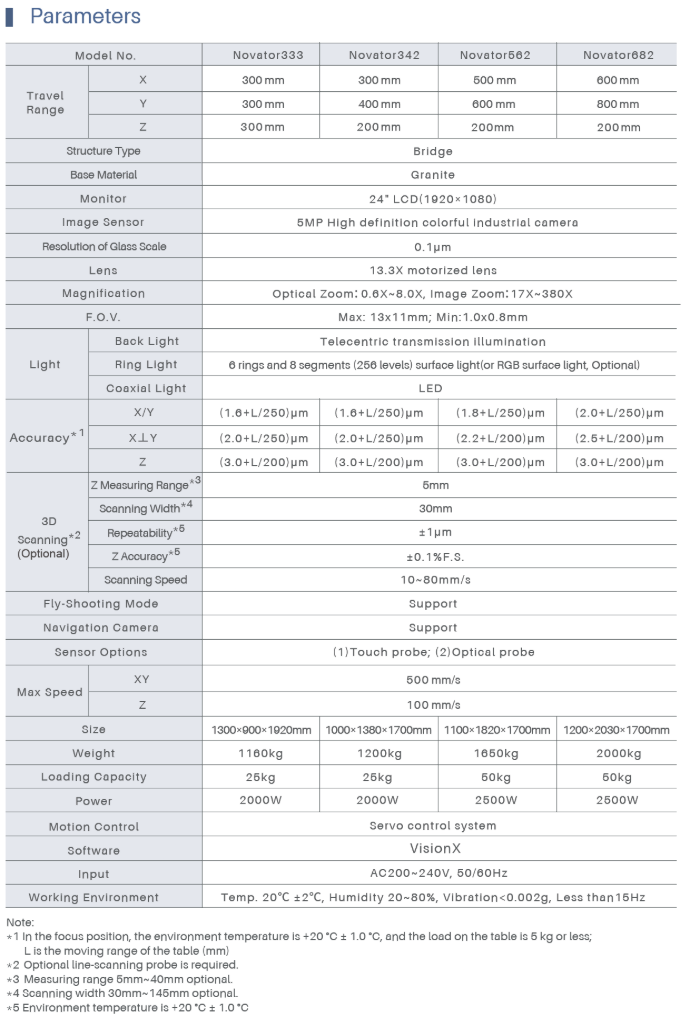

The Novator Series represents a new generation of automatic video measuring systems, combining 2D vision technology with advanced 3D laser scanning and AI-driven image processing. Designed for high-precision dimensional inspection, the Novator delivers unmatched accuracy, speed, and flexibility for complex parts and demanding applications.

Key Features

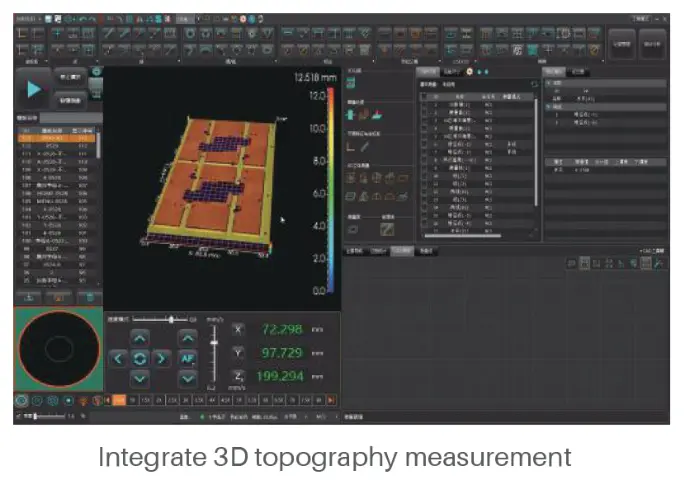

3D Hybrid Measurement: Integrates 2D vision measurement with laser-based 3D scanning for complete profile and topography analysis.

Stable and Accurate: Precision granite structure, high-rigidity bridge design, and servo-controlled linear guide system ensure long-term stability and high accuracy.

High-Speed Measurement: Equipped with strobe lighting and fly-shooting technology, improving measurement efficiency by up to 10 times.

Flexible Lighting: Replaceable RGB/white light, programmable coaxial and back light, and 6-ring/8-segment surface illumination for any material or surface condition.

Batch Automation: CNC-controlled system supports CAD/Gerber file import, automatic coordinate matching, and fast, repeatable batch inspection.

Easy Operation: User-friendly VisionX software, intuitive interface, large FOV navigation camera, and anti-collision safety features simplify operation and training.

Higlights

3. User-friendly operation interface, anyone can easily set and measure.