Precision Measurement, Scanning & Quality Support

BULTECH Global Solutions provides industrial 3D metrology and inspection services to help manufacturers control quality, validate assemblies, and reduce scrap and rework. From on-site dimensional inspection to 3D scanning and reverse engineering, we deliver clear, actionable reports and reliable support for your production and maintenance teams.

Whether you need a fast verification of critical dimensions, a complete scan-to-CAD workflow, or assistance with measurement hardware (linear scales and digital readouts), our mission is simple: turn measurement into confident decisions.

3D Measurement & Dimensional Inspection

When tolerances are tight, you need results you can trust. We perform 3D measurement and dimensional inspection for parts, tools, fixtures, and assemblies—supporting first articles, ongoing production checks, and troubleshooting.

Typical applications

GD&T verification, critical feature checks, assembly alignment

First Article Inspection (FAI) / FAIR support and measurement dossiers

Tooling validation (jigs, fixtures, gauges)

Incoming inspection and supplier quality verification

Deformation, wear, and deviation analysis over time

Deliverables

Clear inspection reports (pass/fail, deviations, annotations)

CAD-to-part comparison and deviation maps (when CAD is available)

Recommendations to correct process drift and improve repeatability

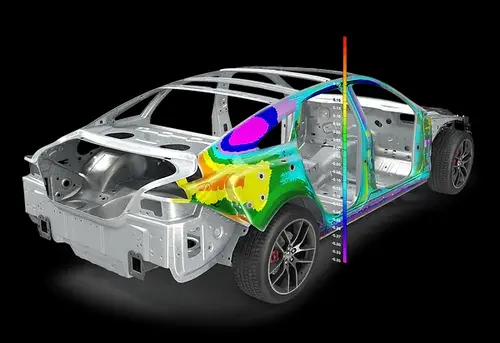

3D Scanning Services

Our 3D scanning services capture complex geometry quickly and accurately for inspection, documentation, and engineering workflows. We adapt the scanning approach to your part size, surface, and required detail.

Use cases

Geometry capture for complex freeform parts

CAD comparison (nominal vs actual)

Surface deviation analysis and color maps

Digital archiving of legacy components

Preparation for reverse engineering and redesign

Common outputs

Point clouds and meshes

Inspection-ready comparisons

Export formats suited for engineering and manufacturing workflows

Reverse Engineering Services (Scan-to-CAD)

From Physical Parts to CAD Models & Manufacturing Data

Need to reproduce a part without drawings, redesign a legacy component, or improve an existing geometry? Our reverse engineering service converts real-world parts into usable digital models.

What we can deliver

Cleaned mesh and reference geometry

CAD reconstruction (from basic to complex surfaces, depending on needs)

Fit/function focused redesign support

Manufacturing-ready datasets (where applicable)

This is ideal for obsolete spare parts, custom adaptations, and modernization projects.

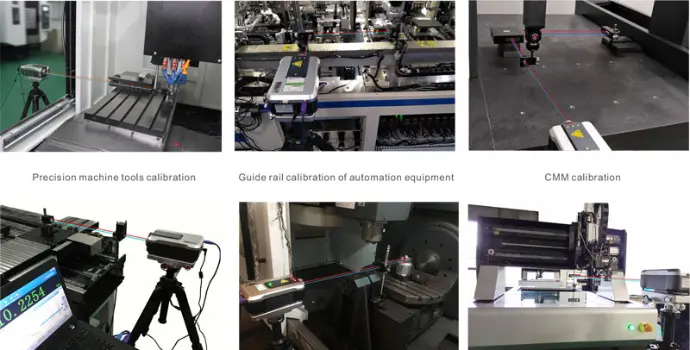

CMM & Machine Tools Calibration & Verification Support

A CMM is only as valuable as its measurement confidence. We provide CMM verification and performance checks to help you maintain accuracy and consistency over time.

Services

Periodic verification and performance testing (as required by your quality system)

Baseline checks after relocation, crash events, or maintenance

Repeatability checks and practical guidance for improving stability

Support for internal audits and measurement traceability documentation

If you need a specific standard or method, we align the verification plan to your requirements and shop-floor reality.

Non-Destructive Testing (NDT) - Inspection & Certification Support

For components where internal integrity matters, we support quality requirements with Non-Destructive Testing (NDT) inspection coordination and reporting aligned to your project specifications.

Typical scope

NDT inspection support based on applicable standards and acceptance criteria

Documentation packages for customers, audits, and compliance needs

Collaboration with qualified personnel and partners when project scope requires it

If your project requires formal third-party certification or a specific accreditation path, we can structure the workflow and documentation to match your customer’s expectations.

Linear Scale & Digital Readout (DRO) Support and Repair Assistance

Service available 7 days a week

Measurement failures on machines can stop production. We provide technical support for linear encoder scales and DRO systems, helping you restore reliability and reduce downtime.

We can help with

Troubleshooting signal issues, reading instability, and wiring faults

Installation support, alignment, and commissioning guidance

Diagnostics for scale/DRO compatibility and retrofit planning

Repair assistance workflow (assessment, recommendation, validation checks)

This service is especially useful for machine tools, manual inspection stations, and retrofit projects where fast recovery matters.

Industries We Support

We commonly support projects in:

Automotive and suppliers

Aerospace and precision machining

Industrial manufacturing and automation

Tooling, molds, and fixtures

Maintenance, retrofit, and repair operations

How We Work

Define requirement (tolerances, standards, deliverables, timeline)

Plan the measurement (setup strategy, reference system, constraints)

Measure / scan / inspect on-site or at your location

Analyze and report with clear results and deviations

Follow-up support for corrective actions or repeat inspections

Request a Quote

Tell us what you need to measure or validate (part type, size, tolerance level, location, and deadline). We’ll respond with a practical plan, estimated lead time, and the best approach for your quality objective.

Call to action: Contact us via the website form to start your project.

FAQ

Do you work on-site?

Yes—on-site inspection and scanning is available depending on project requirements and location.

Which file formats do you deliver?

We can deliver common engineering formats (point clouds/meshes and report documents). If you have a preferred format, we align to your workflow.

How fast can you deliver results?

Turnaround depends on part complexity and reporting depth. For urgent troubleshooting or critical checks, we can prioritize a fast initial report.

Can you support multi-part series inspections?

Yes—production checks and repeat inspections can be structured to track drift and improve process control.

You need a technician in Metrology or a measuring system?

Contact us today and we will provide a solution