Microscope VT6000

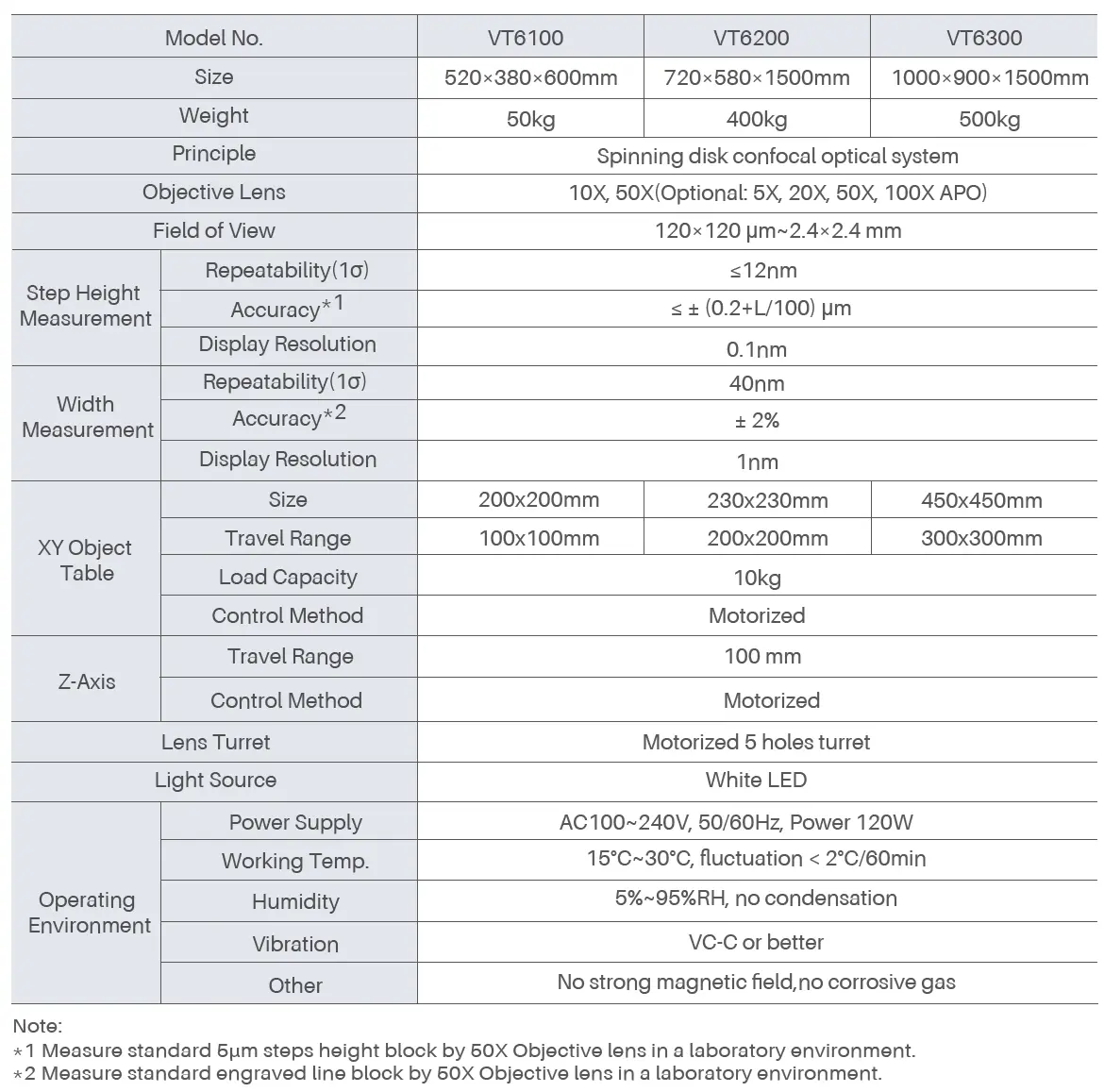

Description Key Features Software: XtremeVision 3D Application Applications Cases Lens Spec General Spec Videos

VT6000 series – Confocal Microscope

White Light Interferometry | Nano 3D Surface Form & Roughness

foreign standards ISO/ASME/EUR/GBT are provided as evaluation standards.

Key Features

High precision and high repeatability

- Based on the rotating confocal optical system, combined with high stability structural design and excellent 3D reconstruction algorithm, the measurement system is jointly composed to ensure the high measurement accuracy of the instrument.

- The unique shock isolation design can reduce the vibration noise of the bottom surface, the instrument is stable and reliable in most environments, and has good measurement repeatability.

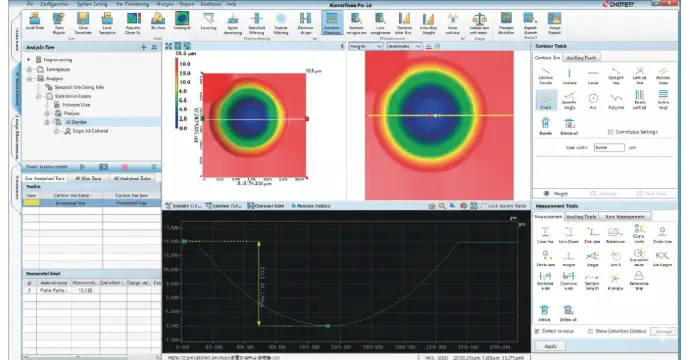

All-in-one operation of measurement analysis software

The measurement and analysis are operated on the same interface without switching, and the measurement data is automatically counted, realizing the function of rapid batch measurement.

The visualization window is convenient for users to observe the scanning process in real time.

Combined with the automatic measurement function of the custom analysis template, the multi-region measurement and analysis can be automatically completed.

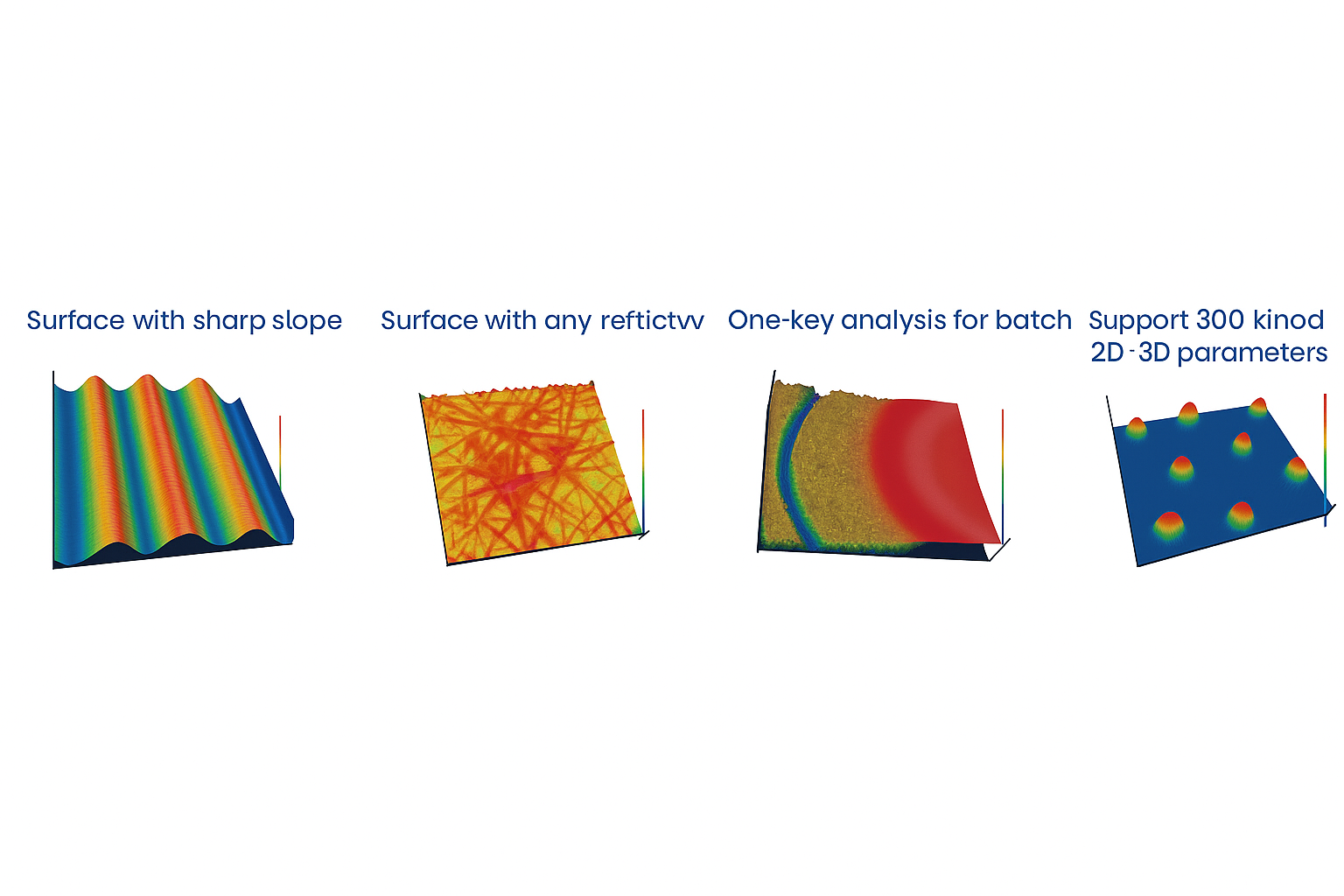

Five functional modules of geometric analysis, roughness analysis, structural analysis, frequency analysis and functional analysis.

One-key analysis, multi-file analysis, free combination analysis items are saved as analysis templates, one-key analysis of batch samples, and data analysis and statistical chart functions are provided.

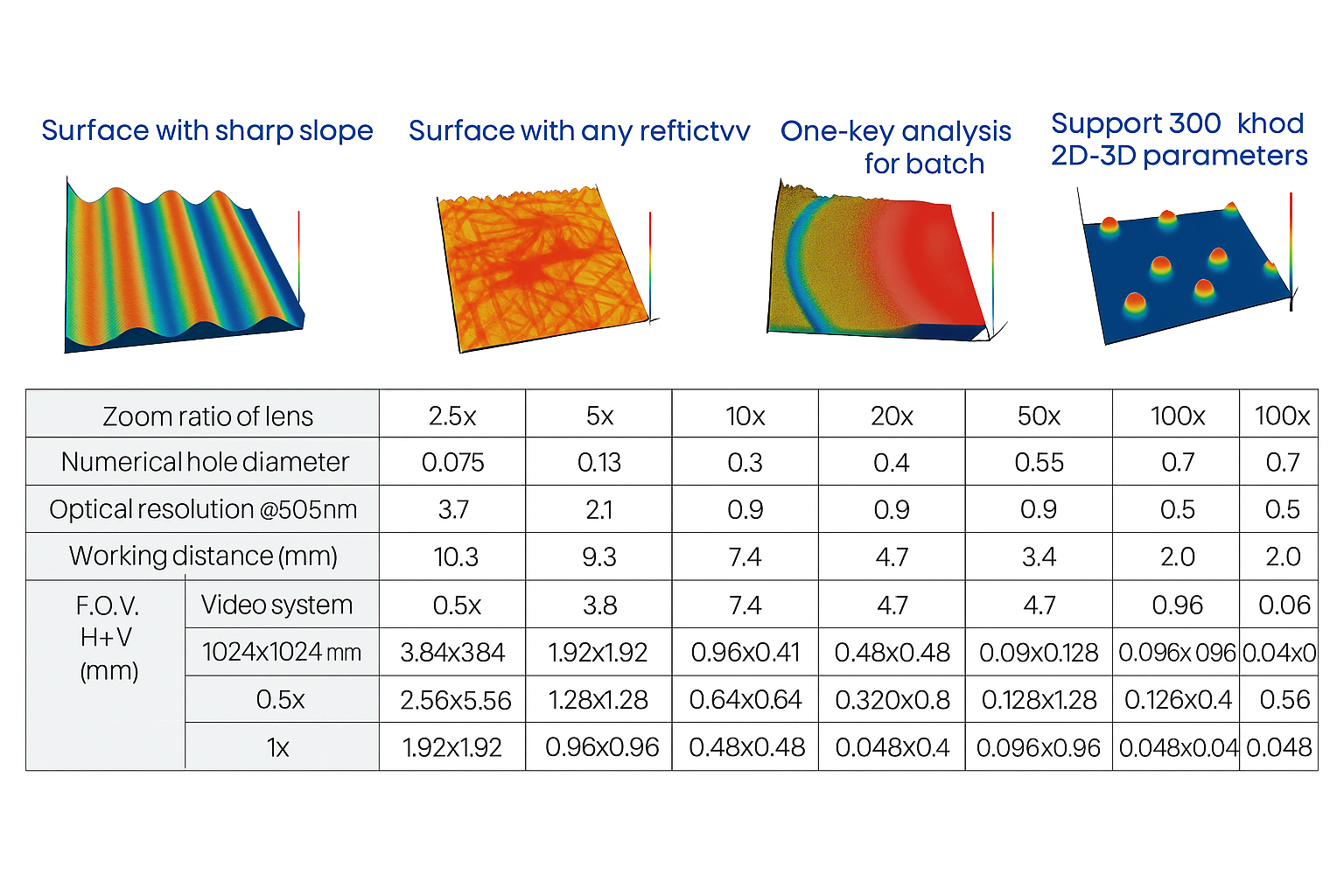

More than 300 kinds of 2D and 3D parameters can be measured according to ISO/ASME/EUR/GBT.

Precision joystick

The joystick integrated with the displacement adjustment functions in the three directions of X, Y, and Z can quickly complete the pre-measurement works such as stage translation and 2-way focusing etc.

Double anti-collision protection measures

In addition to the software ZSTOP setting the lower limit of the Z-direction displacement for anti-collision protection, a mechanical and electronic sensor is designed on the Z-axis. When the lens touches the surface of the sample, the instrument automatically enters an emergency stop state to protect the instrument to the greatest extent and reduce the risk of human operation.

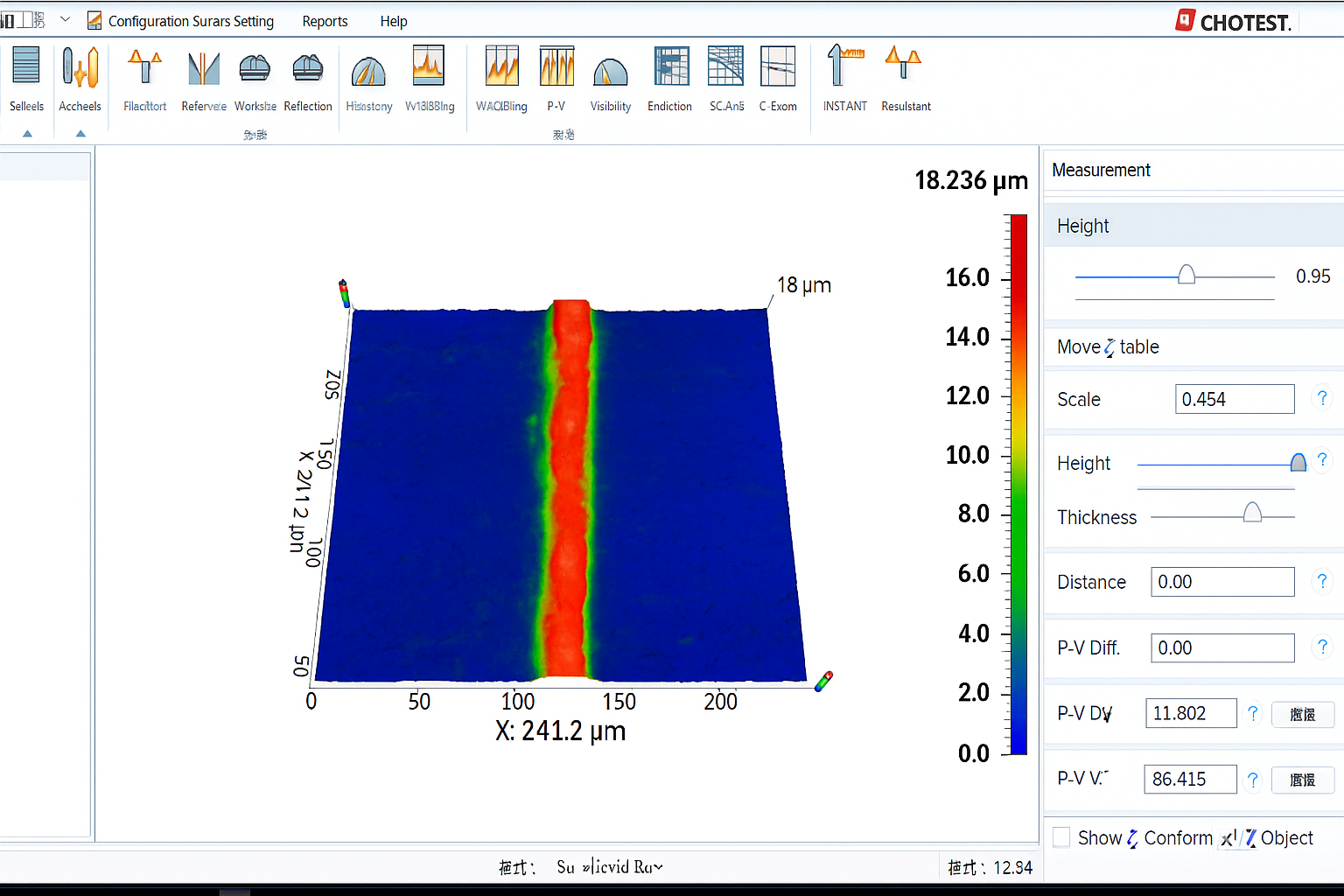

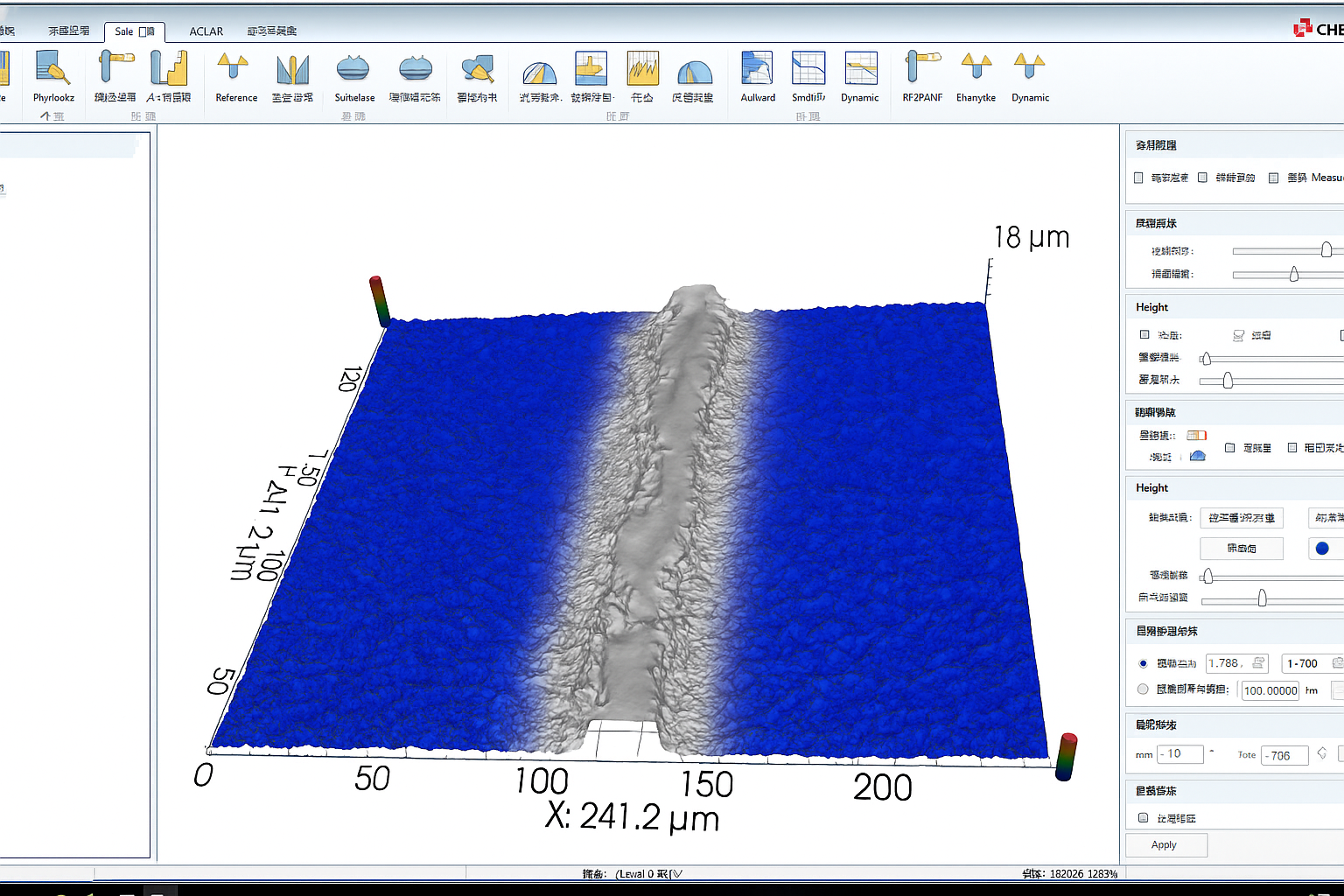

Software: XtremeVision 3D

The integrated XtremeVision 3D software combines:

3D image scanning & analysis

Automated measurement

Intelligent noise filtering

Hybrid scanning (white light interferometry + confocal)

It allows automatic feature recognition and step height measurement with repeatability as fine as 0.005μm and step accuracy of 0.08%.

point-line distance, angle, radius, etc.

Application

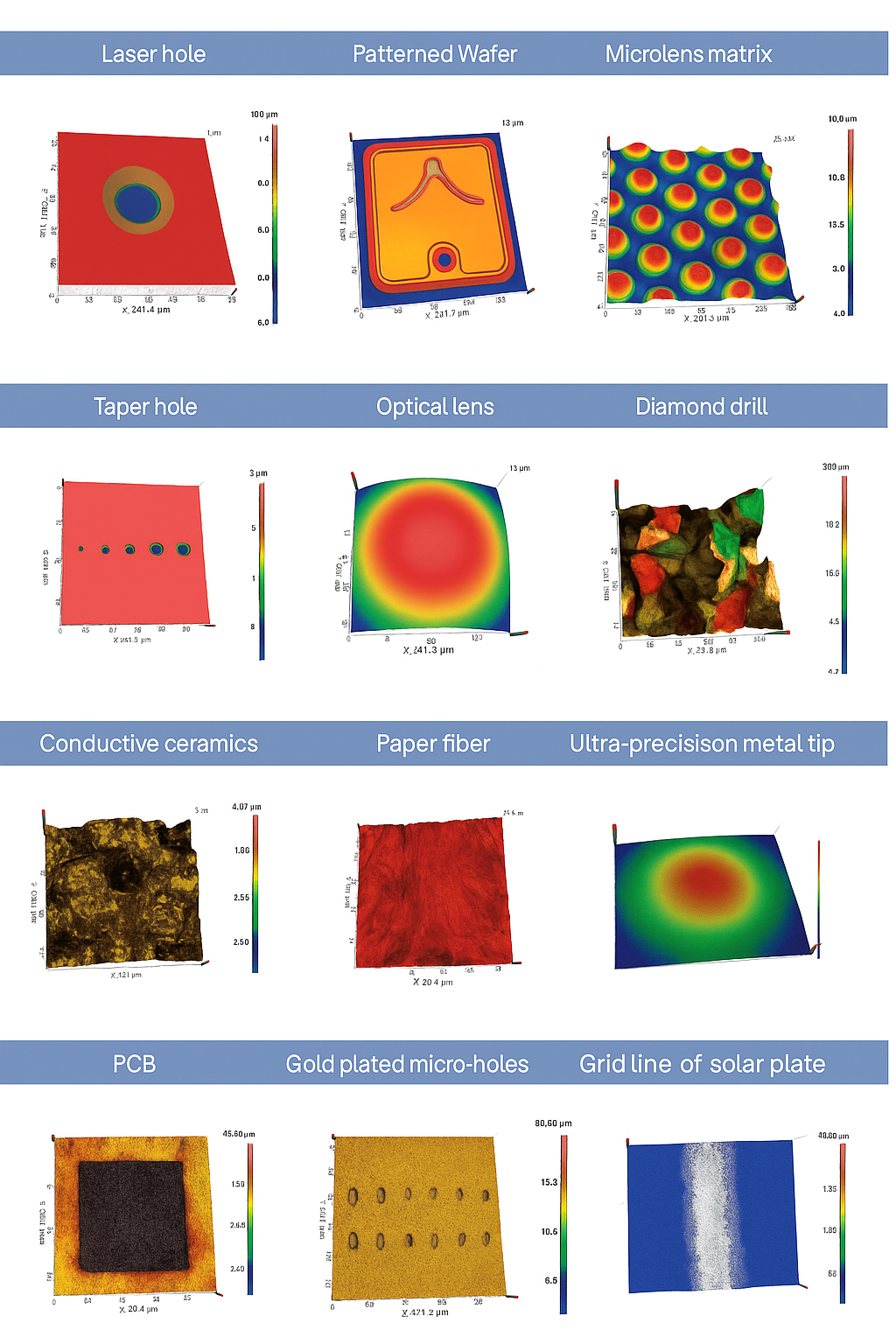

micro-nano materials, micro-electro-mechanical system.

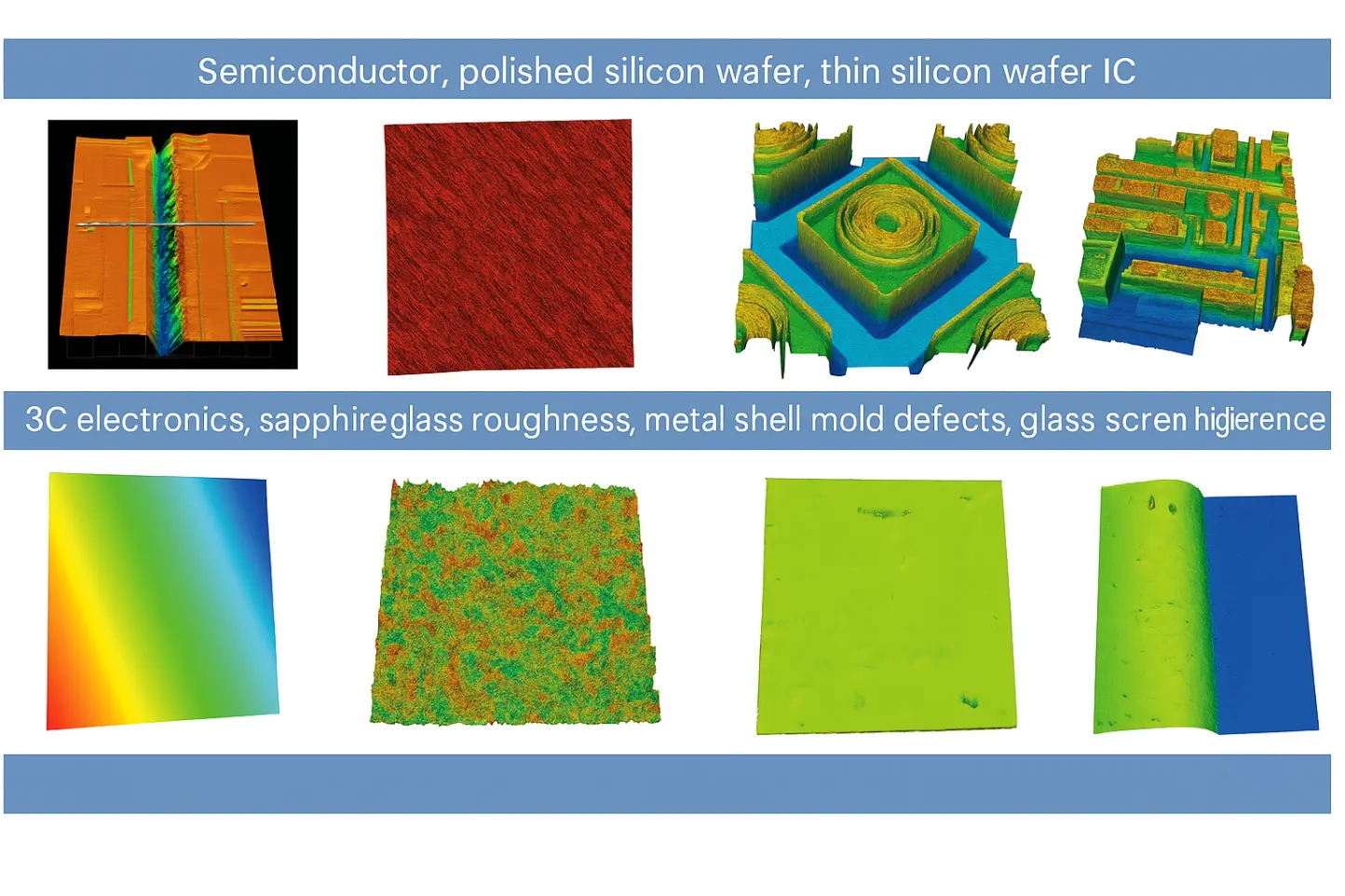

Application Cases

Measurement and analysis for various products, components and materials`surface form and profile characteristics, such as flatness, roughness, waviness, appearance, surface defect, abrasion, corrosion, gap,hole, stage, curvature, deformation.

V-shaped groove - Trench - Pyramid shape

Lens Specification

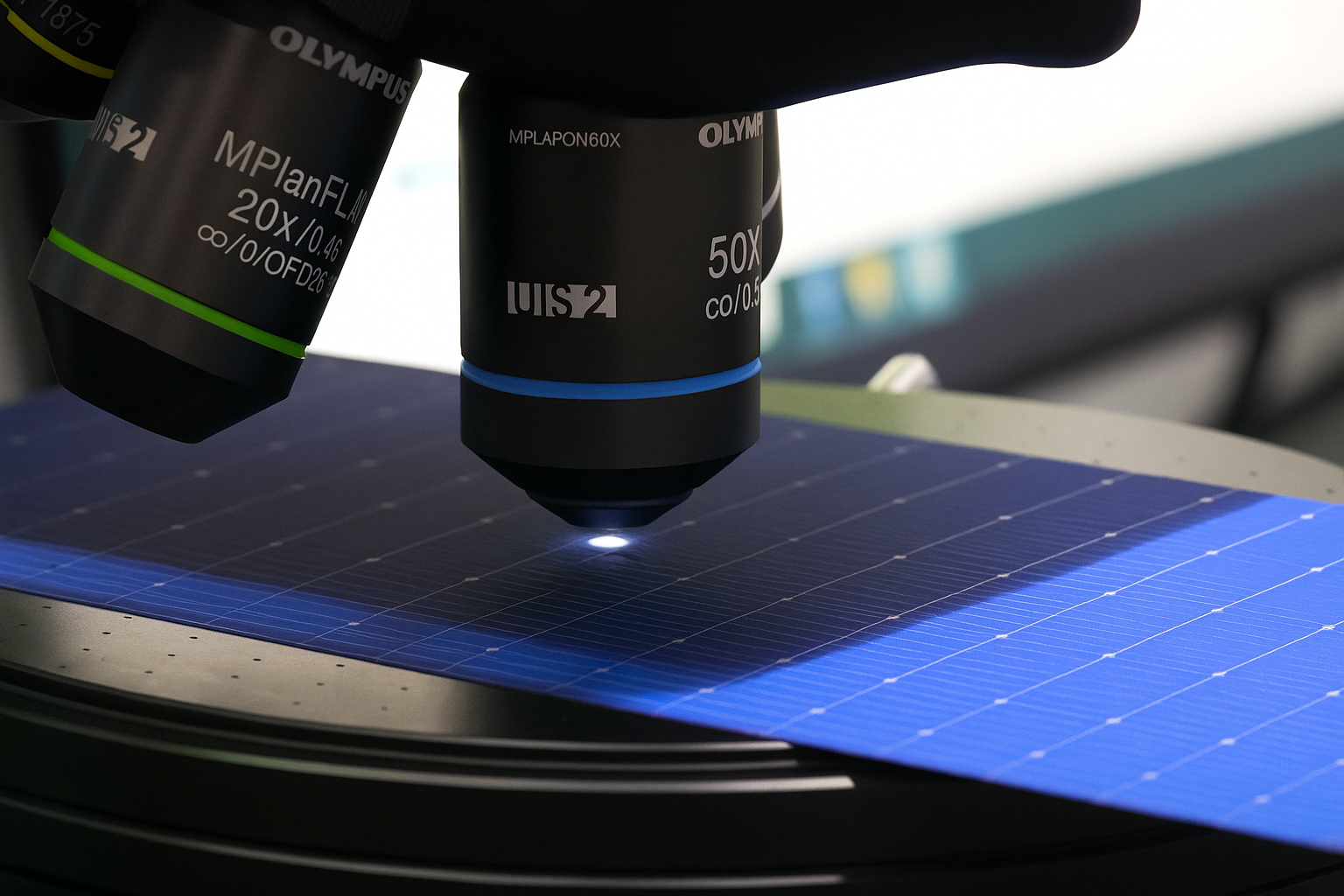

VT6000 confocal MicroscopeMeasures Solar cell Grid Size

VT6000 confocal Microscope Measures Solar cell Grid Size