VX & Hybrid series

Flash Measuring Machines – High-Speed, High-Precision Inspection

Description

The Flash Series measuring machines are designed to deliver ultra-fast, fully automated dimensional inspection for complex parts across a wide range of industries. Combining advanced optics, intelligent illumination, and powerful measurement algorithms, Flash systems provide one-click measurement of multiple features with high accuracy and repeatability.

Equipped with telecentric optics, programmable multi-segment lighting, and AI-powered edge detection, these machines overcome common challenges such as blurred contours, low contrast, burrs, or incomplete edges. Measurement processes that traditionally take minutes can now be executed in seconds, significantly improving throughput and efficiency.

The Flash series integrates seamlessly with CAD models, SPC reporting, and automated production workflows, making it a key enabler for Smart Factory and Industry 4.0. With its combination of speed, precision, and ease of use, Flash is the ideal solution for electronics, automotive, medical, plastics, and precision engineering industries.

In short: The Flash Series transforms dimensional inspection into a fast, simple, and reliable process — ensuring higher productivity and uncompromised quality.

Efficient Measurement

- Auto Illumination

- Auto Focusing

- More than 5000 features

- Can handle up to 1024 workpieces simultaneously

- 2 sec to finish the measurement

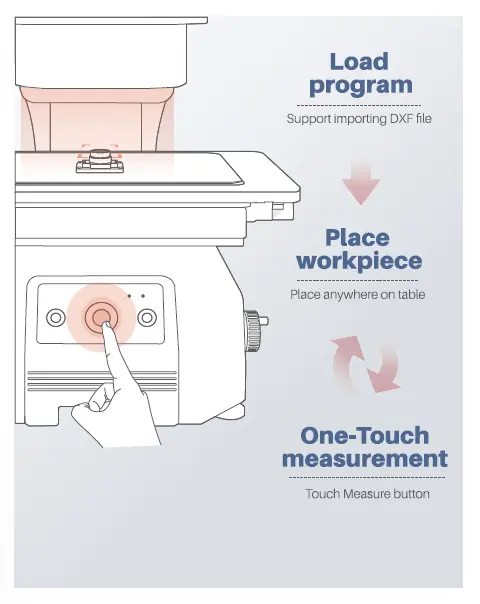

- Supporting importing DXF file

- Place workpiece anywhere on table

- One Touch measure button

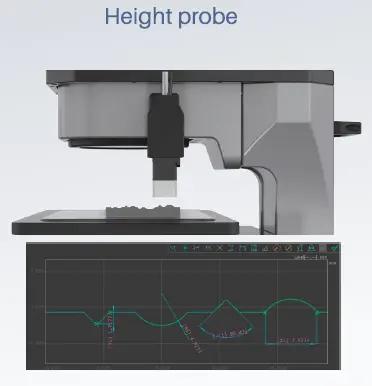

3D Optical Profilometer

- Offers comprehensive surface analysis and micro-nano measurement capabilities.

- Equipped with high-resolution imaging and advanced algorithms for edge detection.

- Ideal for applications in automotive, aerospace, and machinery industries.

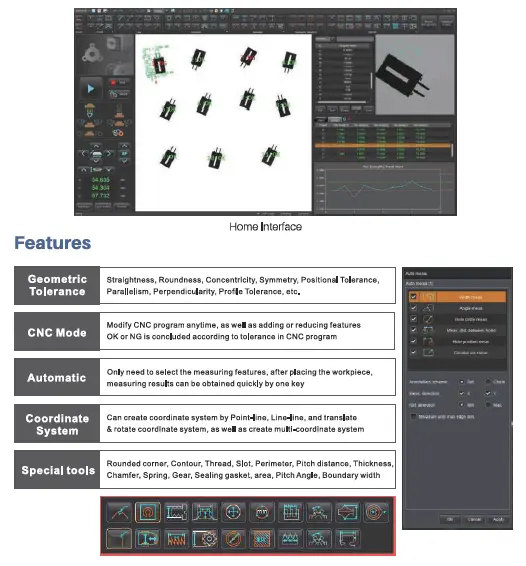

Vision X Software

- Developed independently by Chotest, featuring a user-friendly interface.

- Supports over 80 extraction and analysis tools for various measurement needs.

- Allows for automatic data collection and statistical analysis of measurement results.

- DXF Import.

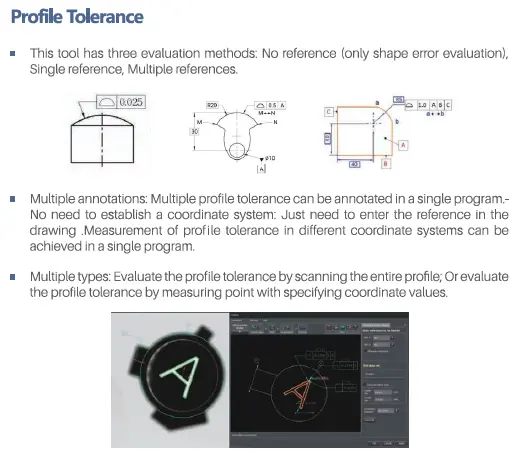

- Profile Tolerance.

- QR Code Recognition.

Smart Functions supporte by AI

- Automatic Multi Object Matching with 360 degree rotation search function.

- Extract multi-circle by lasso.

- Seal Measurement, accurate measurements can be performed even for seal rings with large deformation.

- Ideal for applications in automotive, aerospace, and machinery industries.

- Suitable for measuring components like phone cases, gears, and rubber seals.

- Provides accurate measurements even for deformed samples.

- Smart Profile and position tolerance.

- QR Code recognition on part able to call the right measuring program.

- TCP command for automation

- Data transfer to QDAS

VX8100/VX8200/VX8300

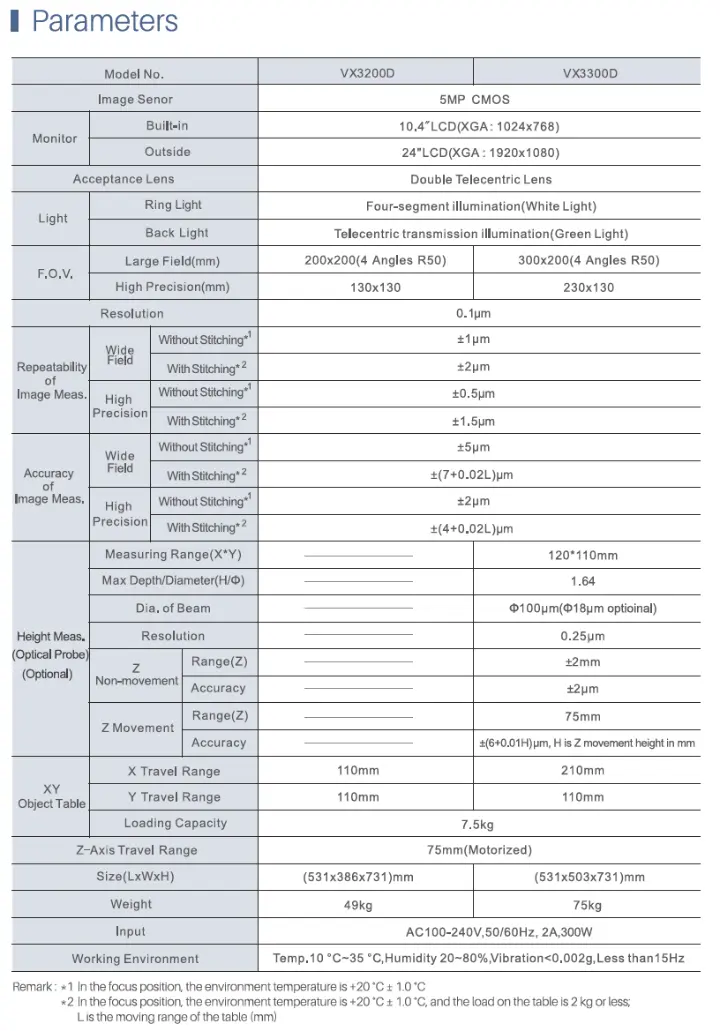

VX3200D/VX3300D