NDT Solutions

Non Destructive Testing

Our portfolio ranges from individual devices to complete turnkey solutions, including the implementation of complex multi-method NDT systems, operator qualification and certification, and the establishment of full NDT processes along with the necessary supporting procedures on the shop floor.

The long-term goal is to increase the volumes of NDT products through outsourcing and improved reproducibility and traceability of performed tests. This principle is applied both in the provision of services and in the design and production of equipment.

either by implementing the full process including equipment directly at the customer’s facility, or by outsourcing the customer’s NDT processes to a specialized provider.

Between 2019 and 2021, this approach has been further developed through the introduction of new applications available to customers.

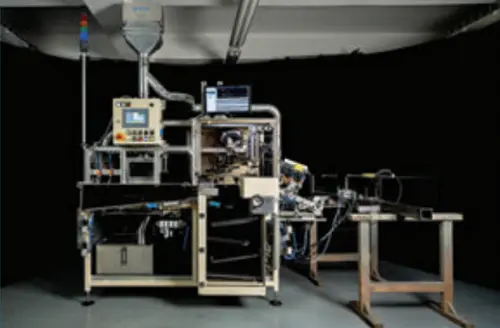

First intelligent VT system (INDUSTRY 4.0) for fully automated testing and defect recognition on bearings

In 2019, the first fully automated iVT-B1 system for visual testing with Automatic Defect Recognition (ADR) was successfully delivered. iVT-B1 is designed for automatic inspection of 100% of the outer and inner surfaces of bearings, including faces and signatures, with a cycle time of just 11 seconds.

The system achieves a registration threshold of 0.1 mm for defects such as scratches, pressure marks, corrosion, burnouts and others. Its core integrates precise manipulation, advanced cameras, lighting, deep-learning software and an intuitive user interface. It also features automated sorting of OK/NOK parts and anti-corrosion treatment of bearings.

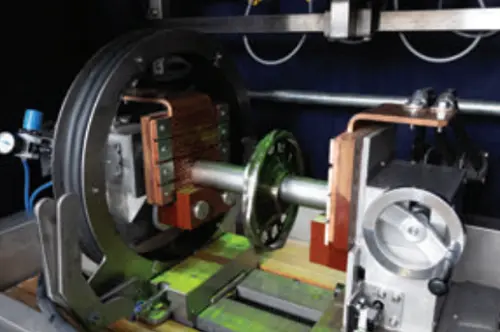

New semi-automated UNIMAG WST for testing railway wheelsets

In 2021, the first UNIMAG WST system was delivered for railway wheelset testing according to VPI 09. This system significantly increases productivity (from 60 minutes to 18 minutes per wheelset), quality and testing reliability in the railway industry.

The equipment includes integrated mirrored coils of various types for magnetizing wheels, contact surfaces, hubs and axles, combined with automated lifting, rotation and magnetic suspension handling. Additional options allow magnetization of axles only, using current flow.

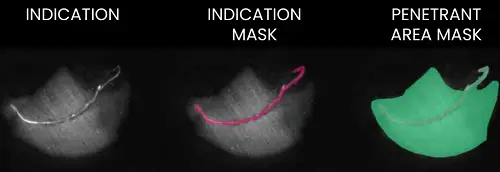

New UNIMAG Aerotester NG family enters serial production

The UNIMAG Aerotester NG series represents a major upgrade of the proven horizontal MPI benches, already widely used in aerospace MRO and OEM facilities worldwide. The equipment is built in stainless steel, designed with minimal footprint thanks to integrated switchboards and a foldable cabin. It features modern electronics for precise control of AC, HWDC and 3xFWDC currents, fully compliant with ASTM E1444 and major OEM specifications (Boeing, Rolls Royce, Pratt & Whitney, GE Aviation, Honeywell).

The system offers a 5% duty cycle, two power setups (FWDC 6 kA or 10 kA), clamping lengths up to 1400, 3000 and 4200 mm, and coil diameters of 300, 400, 500 or 630 mm.

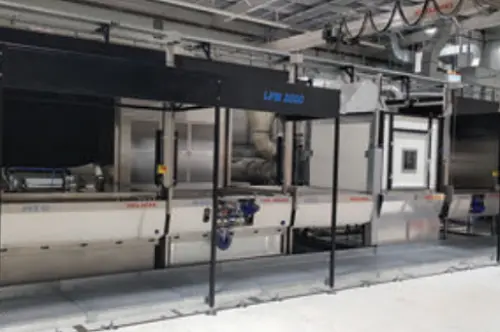

LPM 2600 MAX – First FPI line delivered to Australia

At the beginning of 2021, despite COVID-19 restrictions and compulsory quarantine, the first LPM 2600 MAX fluorescent penetrant inspection line was successfully installed in Brisbane, Australia. This system is designed for both civil and military aerospace industries, supporting MRO operations for J135 engines of the F-35 Lightning II fighter jet (RAAF).

The line is built entirely from stainless steel, with each station sized 1550 x 1550 mm. Penetrant application is performed by immersion or electrostatic spraying, with part movement via roller tracks or overhead crane. The system includes a high-performance oven, developer application by electrostatic spraying, LED-based white/UV lighting and powerful ventilation to ensure safe and comfortable working conditions.

Non Destructive Testing business Unit

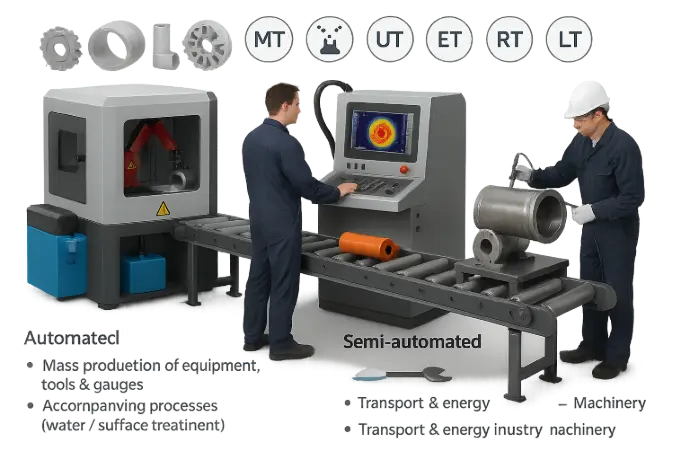

PRODUCTION AND EQUIPMENT

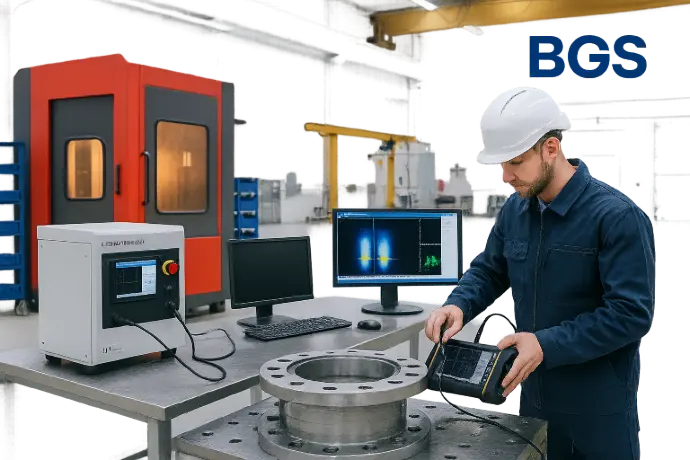

TESTING AND INSPECTION

Inspection in petrochemical and energy industry

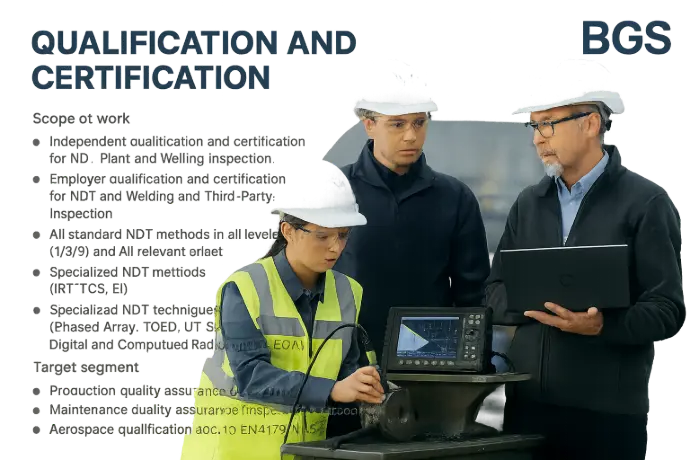

QUALIFICATION AND CERTIFICATION

Aerospace qualification acc. to EN4179/NAS410

OUTSIDE AGENCY SERVICES

Some applications

Intelligent visual SYSTM iVT B-1 fir testing of bearings (AUTOMOTIVE)

In 2019, the first fully automated iVT-B1 system for visual testing with Automatic Defect Recognition (ADR) was successfully delivered. iVT-B1 is designed for automatic inspection of 100% of the outer and inner surfaces of bearings, including faces and signatures, with a cycle time of just 11 seconds.

The system achieves a registration threshold of 0.1 mm for defects such as scratches, pressure marks, corrosion, burnouts and others. Its core integrates precise manipulation, advanced cameras, lighting, deep-learning software and an intuitive user interface. It also features automated sorting of OK/NOK parts and anti-corrosion treatment of bearings.

New semi-automated UNIMAG WST for testing railway wheelsets

In 2021, the first UNIMAG WST system was delivered for railway wheelset testing according to VPI 09. This system significantly increases productivity (from 60 minutes to 18 minutes per wheelset), quality and testing reliability in the railway industry.

The equipment includes integrated mirrored coils of various types for magnetizing wheels, contact surfaces, hubs and axles, combined with automated lifting, rotation and magnetic suspension handling. Additional options allow magnetization of axles only, using current flow.

New UNIMAG Aerotester NG family enters serial production

The UNIMAG Aerotester NG series represents a major upgrade of the proven horizontal MPI benches, already widely used in aerospace MRO and OEM facilities worldwide. The equipment is built in stainless steel, designed with minimal footprint thanks to integrated switchboards and a foldable cabin. It features modern electronics for precise control of AC, HWDC and 3xFWDC currents, fully compliant with ASTM E1444 and major OEM specifications (Boeing, Rolls Royce, Pratt & Whitney, GE Aviation, Honeywell).

The system offers a 5% duty cycle, two power setups (FWDC 6 kA or 10 kA), clamping lengths up to 1400, 3000 and 4200 mm, and coil diameters of 300, 400, 500 or 630 mm.

LPM 2600 MAX – First FPI line delivered to Australia

At the beginning of 2021, despite COVID-19 restrictions and compulsory quarantine, the first LPM 2600 MAX fluorescent penetrant inspection line was successfully installed in Brisbane, Australia. This system is designed for both civil and military aerospace industries, supporting MRO operations for J135 engines of the F-35 Lightning II fighter jet (RAAF).

The line is built entirely from stainless steel, with each station sized 1550 x 1550 mm. Penetrant application is performed by immersion or electrostatic spraying, with part movement via roller tracks or overhead crane. The system includes a high-performance oven, developer application by electrostatic spraying, LED-based white/UV lighting and powerful ventilation to ensure safe and comfortable working conditions.

iMT systems (intelligent Magnetic Testing) offer semi-automated or fully automated magnetic particle inspection

■ Connection into MES / ERP

The precise and fast fully automatic 9-axis ultrasonic manipulator, UZM 3000 C

Through-Transmission. The output of the inspection is a C-scan and all A-scans of the tested part.

AmmCheck is a fully autonomous system for non-destructive testing and dimension control,ensuring maximum efficiency and precision for military production.

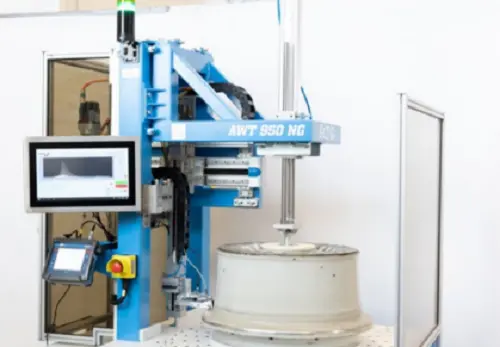

The Advanced Wheel Tester AWT 950 NG is designed for Non-Destructive Testing utilizing Eddy Current Testing on aircraft wheels ́ rim surface for a maximum wheel diameter of 950 mm.

NDT for the Industry 4.0

Our presence around the world

specialised in NDT installation and certification of your operator worldwide