FASTSUITE Edit — simulation software for robotic — Powerful Support of Robot‑Based Welding

Shorter cycle times. Higher flexibility. Fewer tryouts. Combine strong offline programming (OLP) with shop‑floor know‑how to get it right the first time across arc and laser welding cells.

Powerful Support for Robot-Based Welding Applications

Robotic welding has become a key technology in modern manufacturing. Yet, as production evolves, industries demand more flexibility, shorter cycle times, and zero trial errors.

FASTSUITE Edition 2 answers these challenges by combining powerful Offline Programming (OLP) tools with human expertise and process knowledge — empowering your shop floor to achieve perfect results the first time.

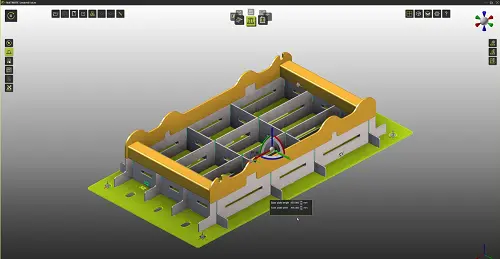

Automatic part Fixture building!

Arc Welding – Precision and Flexibility

Developed for advanced welding requirements in heavy machinery, steel construction, and production industries, FASTSUITE provides:

Optimized strategies for box welding, stitch/tack welding, and multi-layer welding

High automation level with reuse of proven welding parameters

Interactive optimization for consistently high results

Scalable solutions for single-robot to multi-robot environments, independent of robot brand or model

Laser Welding – High Quality and Efficiency

With full support for systems such as TRUMPF TruLaser Weld 5000, TruLaser Robot 5020, and Amada FLW 4000 M3, FASTSUITE delivers:

Seamless CAD integration (STEP, IGES, JT, CATIA, NX, SolidWorks, etc.)

CAD-to-path algorithms for automatic weld path creation

Intuitive process parameter adjustment via user-friendly interface

Integrated WPS (Welding Procedure Specification) database

Automatic positioning and external axis interpolation for perfect part orientation

On-site support from experts for cell calibration and process optimization

The Result:

Whatever your welding process, FASTSUITE enables you to generate accurate, error-free, and homogeneous programs, achieving top-level quality and productivity — all through intelligent offline programming.

Revolutionizing Welding Fixtures

The latest version of FASTSUITE introduces a major upgrade to its fixture builder, extending its use from laser cutting to arc welding applications. Users can now design and optimize arc welding fixtures directly within the OLP environment, without needing external CAD tools or engineering support. The intuitive 3D interface allows easy planning, viewing, and adjustment of fixtures, ensuring high precision and adaptability. This new functionality is specifically optimized for arc welding, preventing part slippage and enhancing overall efficiency and accuracy.

New features with edition 2

Discover the latest features that will take your offline programming to the next level. From enhanced fixture building to smarter automation, this update is packed with powerful improvements.

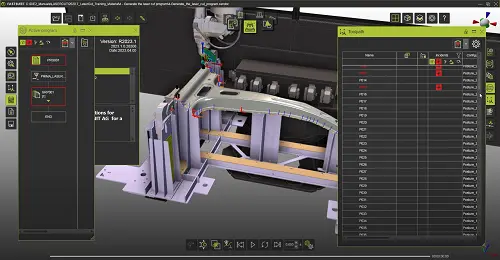

Revolutionizing Robotics: Automatic Toolpath & Linking Optimization | Fast Path Edition 2

The video presents Fast Path Edition 2, showcasing its automatic toolpath optimization and linking path generation features that greatly improve efficiency in robotics and machining. It demonstrates how the software enables fully automated, collision-free toolpaths, reducing manual programming time and energy use. Compatible with laser cutters, 5-axis machines, and complex robot systems, Fast Path Edition 2 adapts to diverse industrial needs — delivering smarter, faster, and more efficient automation.